Introduction

When purchasing clothing, one of the key factors people often overlook is the color fastness of the fabric. Color fastness refers to the fabric’s ability to maintain its color when subjected to various conditions such as washing, exposure to light, perspiration, and friction. Poor color fastness can result in fading, staining, and overall reduced garment quality, leading to customer dissatisfaction. This article explores the importance of color fastness in clothing fabrics, its impact on garment longevity, and practical tips on selecting fabrics with high color fastness.

1. What is Color Fastness?

Color fastness refers to a fabric’s resistance to fading or running during wear, washing, and exposure to environmental factors. It’s an important quality indicator in the textile industry, as it ensures that clothing retains its vibrant appearance and prevents the transfer of dye to other clothing or skin. Several types of color fastness are tested in fabrics, including:

- Light fastness: Resistance to fading due to exposure to sunlight or artificial light.

- Wash fastness: Resistance to fading or bleeding during laundering.

- Rub fastness: Resistance to color loss when the fabric is rubbed against another surface.

- Perspiration fastness: The fabric’s ability to retain color when in contact with sweat.

Each type of fastness is tested using different methods, and ensuring high levels in all these aspects is crucial for maintaining fabric quality and consumer satisfaction.

2. Why is Color Fastness Important?

2.1. Consumer Satisfaction

Color fastness directly impacts the consumer’s experience with the garment. Poor fastness can lead to fading, bleeding, or dye transfer, leaving the customer dissatisfied with the quality. For example, a brightly colored shirt that fades after just a few washes will be seen as low-quality. Clothing with poor color fastness can also cause dye to rub off onto other garments or skin, which is particularly frustrating for consumers.

2.2. Garment Durability

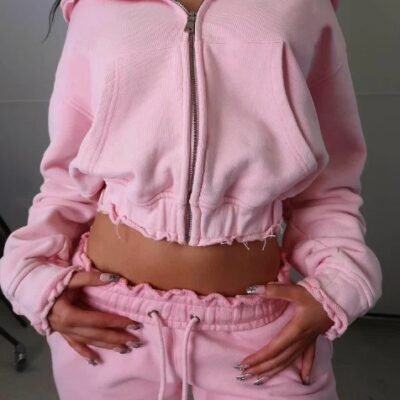

High color fastness contributes to the overall durability of clothing. Garments that maintain their original colors after multiple washes and wear cycles are perceived as longer-lasting and better investments. This is particularly important for frequently washed items such as athletic wear, yoga clothing, and children’s garments. Without high color fastness, the garment’s appearance can degrade quickly, reducing its lifespan.

2.3. Brand Reputation

For manufacturers and retailers, color fastness plays a significant role in brand reputation. Consistently producing or selling clothing with poor color retention can harm a brand’s image, as customers are less likely to repurchase or recommend products that don’t last. Ensuring that fabrics have high color fastness builds trust with consumers, leading to increased loyalty and sales.

3. Factors Affecting Color Fastness

Several factors influence the color fastness of a fabric, and understanding these can help in selecting high-quality fabrics:

3.1. Dye Type

The type of dye used on the fabric plays a major role in determining its color fastness. Some dyes, such as reactive dyes, have strong chemical bonds with fibers, leading to higher wash fastness. Pigment dyes, on the other hand, may not bond as strongly with the fabric, leading to lower color retention. Different fabric types also interact with dyes in different ways; for instance, natural fibers like cotton and wool often retain color better than synthetic ones.

3.2. Fabric Composition

The composition of the fabric itself is another determining factor. Natural fibers such as cotton, wool, and silk generally absorb and retain dye better than synthetic fibers like polyester and nylon. However, advancements in fabric technology have introduced treatments and processes to improve the dyeing capabilities of synthetic fibers.

3.3. Dyeing Process

The dyeing process, including the application method, temperature, and duration, also influences the color fastness. Poorly executed dyeing methods or shortcuts taken during production can result in uneven coloration and lower fastness levels. Fabrics that are dyed using high-quality, controlled processes generally exhibit better color retention.

3.4. Post-Dyeing Treatments

After dyeing, certain treatments are applied to enhance the color fastness of the fabric. Fixatives, for example, can help bind the dye more effectively to the fabric, reducing fading and bleeding. Fabrics that undergo such treatments typically display higher durability in terms of color.

4. How to Choose Fabrics with High Color Fastness

Selecting fabrics with high color fastness requires careful consideration of the fabric’s characteristics and the intended use of the garment. Below are some practical tips for choosing fabrics with high color fastness:

4.1. Check the Fabric Composition

As previously mentioned, natural fibers like cotton, wool, and linen generally have better dye retention than synthetic ones. When choosing fabrics, look for those made from or blended with these fibers, especially for garments that require frequent washing, such as yoga clothes or sportswear.

4.2. Research Dyeing Methods

Manufacturers that invest in quality dyeing processes and use advanced technologies are more likely to produce fabrics with better color fastness. If possible, ask suppliers about the dyeing methods they use and whether they apply any post-dyeing treatments to enhance color retention.

4.3. Request Color Fastness Test Results

Reliable fabric suppliers will usually provide test reports detailing the color fastness of their fabrics. These tests measure the fabric’s resistance to fading, washing, and rubbing, and are graded on a scale, with higher numbers indicating better fastness. Always ask for these reports when sourcing fabrics to ensure you’re selecting high-quality materials.

4.4. Conduct Your Own Tests

If you’re unsure of a fabric’s color fastness, it’s always a good idea to conduct your own tests. A simple test involves dampening a white cloth and rubbing it against the fabric to check for dye transfer. For wash fastness, you can wash a fabric sample according to care instructions and observe any changes in color. These basic tests can give you a good idea of the fabric’s overall quality.

4.5. Choose Darker Fabrics Carefully

Darker colors tend to show fading more easily, so extra care is needed when selecting darker fabrics. Opt for materials that have undergone special treatments or dyes that enhance color retention, particularly for garments that will face heavy use or washing.

Conclusion

The importance of color fastness in clothing cannot be overstated. It directly impacts customer satisfaction, garment durability, and brand reputation. By understanding the factors that influence color retention and making informed choices when selecting fabrics, both consumers and manufacturers can ensure that garments retain their vibrant colors for longer. Whether you’re a designer, retailer, or consumer, paying attention to fabric quality, dye type, and the manufacturing process will help ensure you choose clothing that lasts both in terms of durability and aesthetic appeal.