There are several printing techniques available for T-shirts, depending on your price point and T-shirts design requirements. For large quantities, the most common techniques are plastisol or water-based printing. Additionally, discharge printing and simulated process printing have become popular in recent years. Other techniques such as flocking, foil stamping, and foil simulation are also quite common.

1. Hand-painted T-shirts Printing:

Hand-painted printing involves using a pen to draw on the T-shirt, typically using textile dyes and acrylic paints. Because it is done manually, the experience and skill of the artist greatly influence the entire printing process. Additionally, once a mistake is made, it is difficult to rectify. The cost of materials and labor for hand-painted T-shirts is quite high

2. Screen Printing T-shirts:

Screen printing involves printing colors layer by layer using separate screens. For example, if a T-shirt design has three colors – red, yellow, and blue – three screens are needed, one for each color. Screen printing techniques include water-based printing, plastisol printing, and ink printing.

Water-based printing is one of the most basic screen printing techniques and is widely used on cotton, polyester, and linen fabrics, among others. Its working principle is similar to dyeing, where a specific area of the fabric is dyed the desired color.

However, this technique cannot be used on dark-colored fabrics. Its main advantage is its wide application range, good colorfastness, and relatively low cost for achieving satisfactory results. The limitation of water-based printing is its inability to be used on dark-colored fabrics.

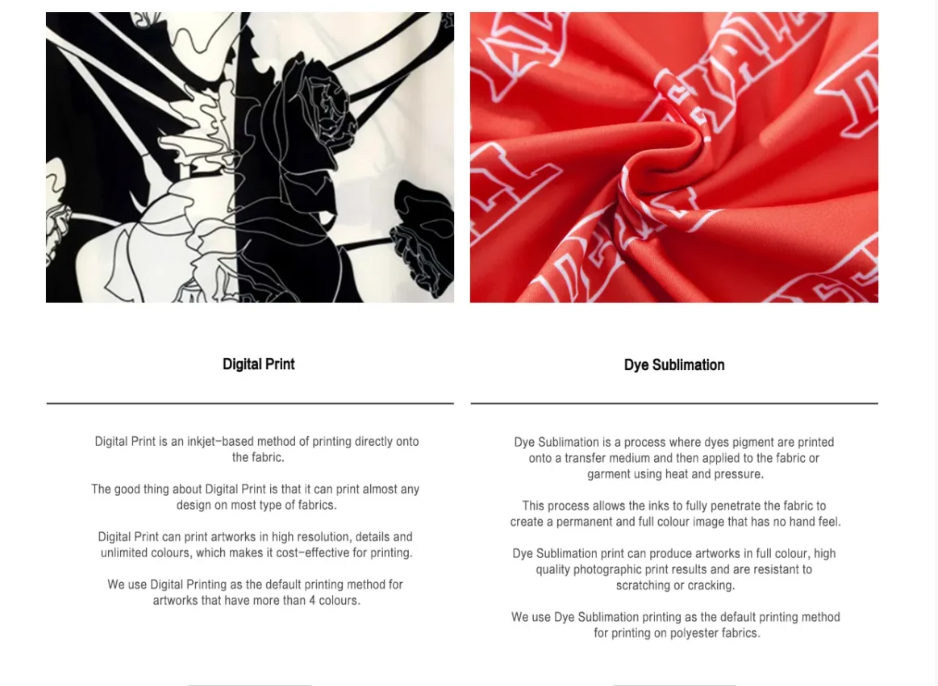

3. Digital Printing:

Digital printing is a newer technology that includes processes such as perforation, splicing, stringing, membrane, and cutting. Although the technology is relatively mature, it still requires professional digital printing machines. Digital direct printing has many advantages, including the ability to print large quantities accurately and consistently. Additionally, the printed patterns are fade-resistant, breathable, odorless, and non-toxic.

4. Heat Transfer Printing:

Heat transfer printing complements screen printing, especially for complex designs that cannot be fully achieved through screen printing alone. Heat transfer involves pressing special paper with the printed design onto the garment using a heat transfer machine. Its advantages include lifelike colors and quick and convenient printing. However, some light-colored designs may not be as clear, and the printed areas may lack breathability.

5. 3D Printing T-shirt:

3D printing involves applying 3D effects to the design and then transferring it onto the T-shirt using heat sublimation digital printing. The printed design on the T-shirt appears three-dimensional, giving it a lifelike appearance. The 3D effect is visible to the naked eye and does not require 3D glasses. The T-shirt itself is flat, and the 3D visual effect is achieved through 3D technology principles.

If you need wholesale custom bulk T-shirts and want to be efficient and save money, contact us and we will all do our best to provide helpful insights to get the most out of the clothing in your printing business!